The Role of Hysteresis in EV Charging

In electric vehicle (EV) charging, precision matters. But so does stability.

Charging systems constantly monitor things like battery level and temperature. These values naturally go up and down slightly—but if the system reacted to every tiny change, it could end up switching on and off too often, causing wear or even confusion.

This is where hysteresis comes in. While it might sound like a complicated technical term, hysteresis is a simple and powerful idea that plays a vital role in charging and other EV functions.

Let’s explore what hysteresis means in practical terms, why it’s important, and how it’s used in EV charging systems.

What is Hysteresis (In Simple and Practical Terms)?

Hysteresis is like a buffer zone that prevents systems from reacting too quickly to small changes.

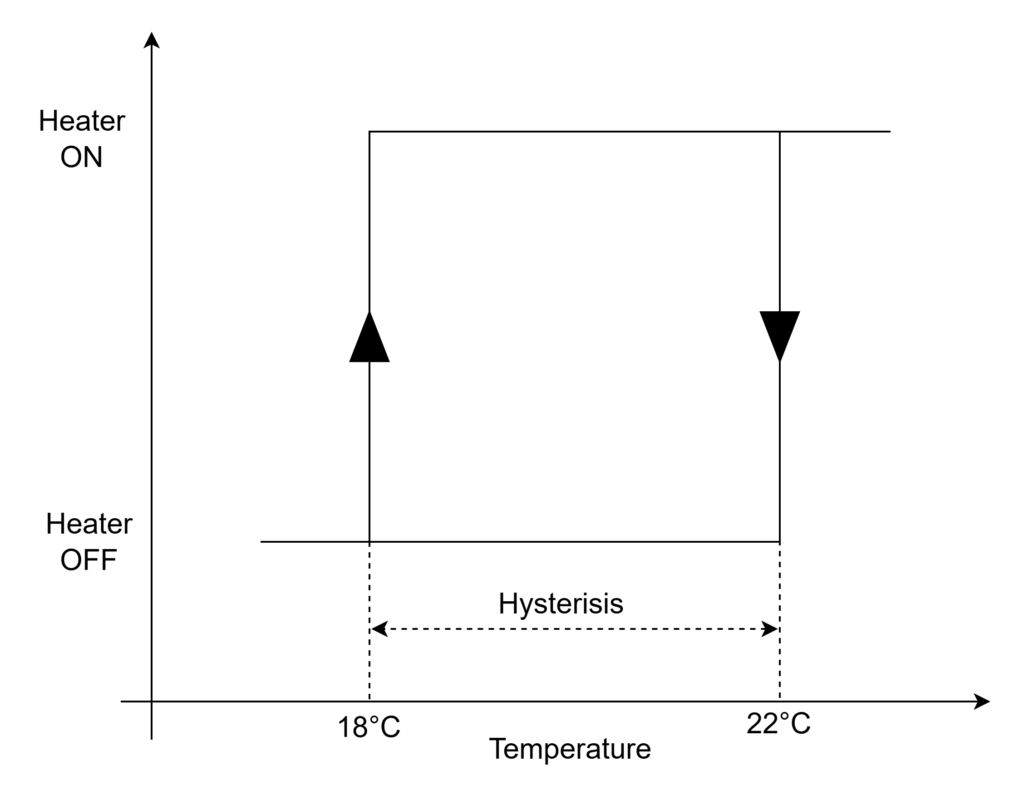

Imagine your home heater:

- It turns on when the room gets cold—say, below 18°C.

- But it doesn’t turn off the moment the temperature hits 18.1°C.

- Instead, it waits until the room warms up to 22°C before turning off.

This small gap between on and off decisions keeps the heater from constantly switching back and forth. That’s hysteresis!

In short: hysteresis helps systems “wait a little” before switching states again—avoiding rapid, unnecessary changes.

Why is Hysteresis Needed?

In any real-world system, measurements like temperature, voltage, or state of charge (SoC) tend to fluctuate slightly due to noise, delays, sensor accuracies, or environmental factors. If the system reacts to every little wiggle:

- It could turn on/off rapidly.

- Create instability.

- Damage hardware components.

Hysteresis solves this by introducing a small margin, ensuring that transitions only occur when the values change significantly.

Where is Hysteresis Used in EV Charging Systems?

Hysteresis is quietly working behind the scenes in multiple places within an EV charging system. Below are the main areas:

- Charging completion detection

- Temperature-related fault handling

- Cooling system control (fans, pumps)

- Voltage-related fault handling

In all these areas, hysteresis keeps the system from behaving erratically when values hover near a threshold.

Hysteresis in Charging Completion Logic

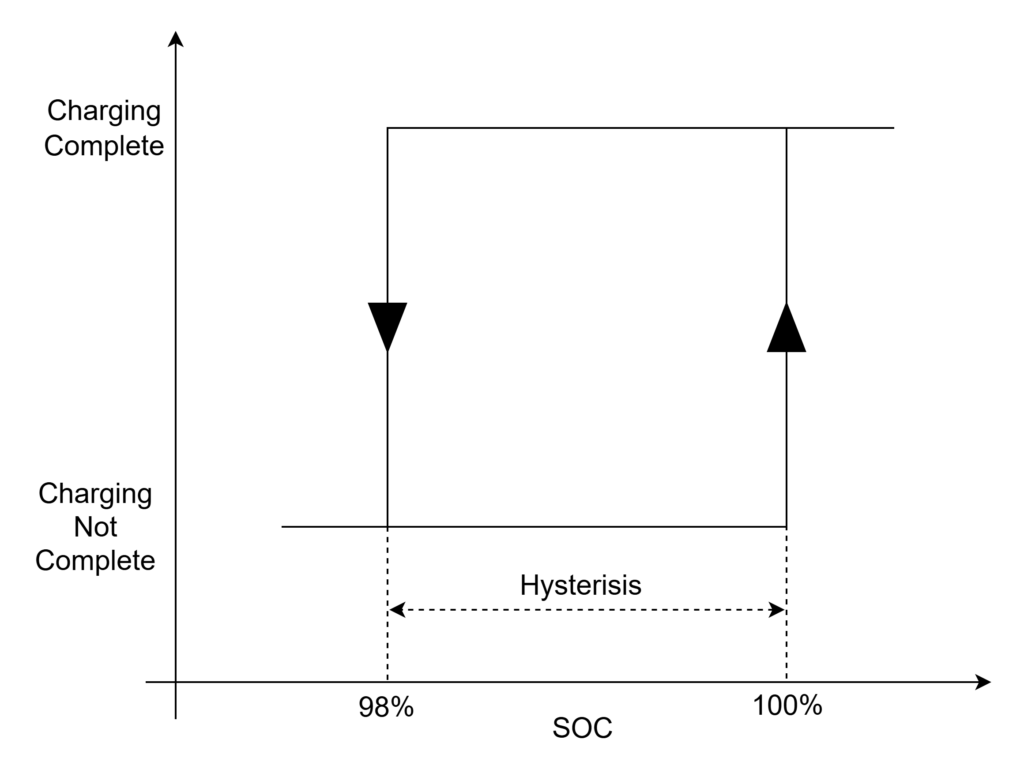

When an EV battery is nearly full, its State of Charge (SoC) can fluctuate slightly due to measurement or estimation in accuracy. Without hysteresis:

- The charging might stop at 100% SoC.

- Then restart charging if the SoC drops to 99.9%.

- This could lead to a rapid on/off loop, which is inefficient and stressful on components.

With 2% of hysteresis:

- Charging stops when SoC hits 100%.

- It resumes only if SoC falls below 98%.

This prevents constant toggling and ensures that charging resumes only when truly needed.

Hysteresis in Temperature Fault Handling

Temperature is a critical safety parameter during EV charging. For example:

- A fault may be triggered if a connector reaches 70°C.

- Without hysteresis, if the temperature drops just a little below 70°C, the fault would turn off—only to come back again a moment later.

With 10°C hysteresis:

- Fault is triggered at 70°C.

- It clears only when the temperature drops below 60°C.

This ensures the system doesn’t repeatedly enter and exit fault mode when temperatures fluctuate near a danger point.

Hysteresis in Temperature Control (Cooling Fans and Pumps)

Cooling systems (like fans and pumps) also rely on hysteresis to avoid excessive cycling.

For instance:

- A fan might turn on at 55°C.

- And only turn off when the temperature drops below 45°C.

This 10°C hysteresis gap ensures that the fan runs long enough to cool the system properly and doesn’t keep turning on/off every few seconds. That saves energy and reduces wear.

Small Margin, Big Impact

Hysteresis might be invisible to most EV users, but it’s doing critical work behind the scenes. From preventing charging loops to keeping cooling systems efficient, hysteresis helps EV charging systems remain stable, smart, and safe.

EV Charging Explained – Everything you need to know about Electric Vehicle Charging